Hardware integration is one of the most popular ways for businesses to improve their workflow and management. It allows companies to have a high-level overview of the entire production process from start to finish.

In this article, you will learn about the basics of hardware and software integration, how it works and how it can help your business.

What is hardware integration?

Hardware integration (also called Hardware-Software integration or system integration) is the process of writing software that connects with one or more pieces of physical hardware to make a single usable system.

Frequently a single piece of hardware works with a companion App to complement its features or provide all of its user-facing functionality such as a display screen and control.

What are the main components of a hardware integrated system?

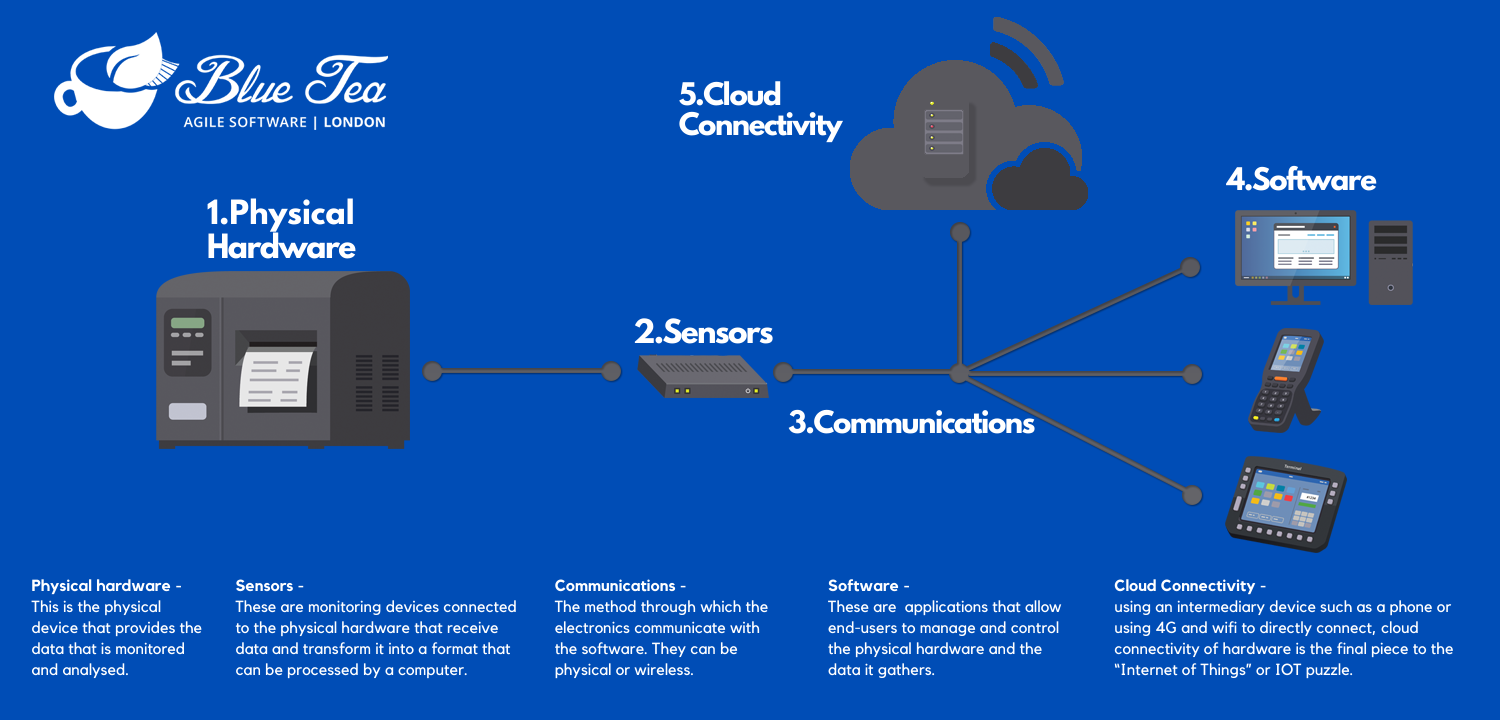

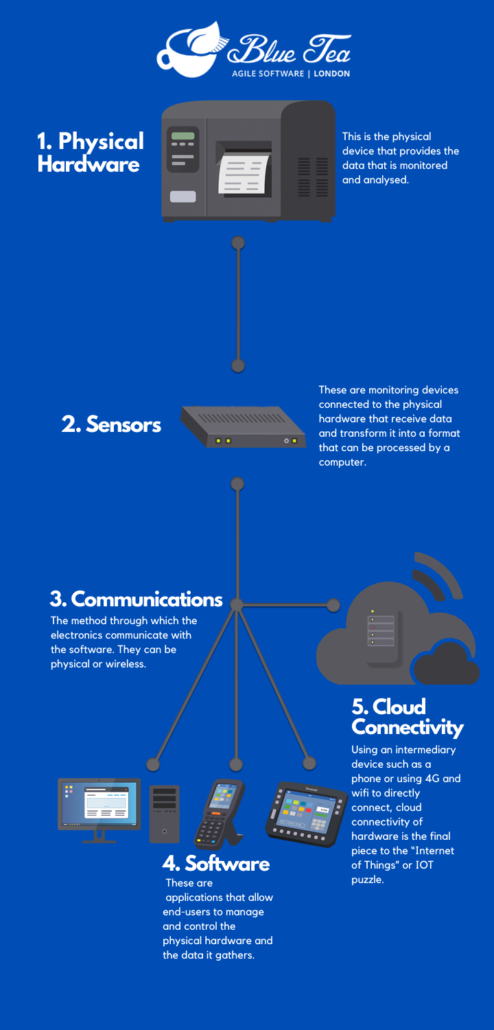

While hardware integrated systems can vary in complexity there are five main components:

- Physical hardware – This is the physical device that provides the data that is monitored and analysed. A few examples of physical hardware include In/Out (I/O) devices, basic integrated circuits and electronics or more complex devices like cameras and small computer systems.

- Sensors – These are monitoring devices connected to the physical hardware that receive data and transform it into a format that can be processed by a computer. These sensors can be thermometers, pressure sensors or specialised timers.

- Communications – The method through which the electronics communicate with the software. The communication can be physical (USB cables, Ethernet cables, HDMI cables, Fibre) or wireless (Wi-fi, Bluetooth and Bluetooth Low Energy).

- Software – These are applications that allow end-users to manage and control the physical hardware and the data it gathers.

The objective of most Hardware integration Apps is to complement the functionality of the hardware system and extend the user interface onto the users device or computer.

Connection of hardware that has no innate internet connectivity of its own to an internet-enabled phone for example can assist with backups, updates and configuration from the cloud - Cloud Connectivity – using an intermediary device such as a phone or using 4G and wifi to directly connect, cloud connectivity of hardware is the final piece to the “Internet of Things” or IOT puzzle.

Further connectivity is of course optional but can be hugely powerful when looking at a large number of devices both in terms of data and management.

Now that you have an overview of what an integrated system looks like let’s see how these systems work in real life.

Examples of Hardware integrated systems

Software controlled lighting equipment for operating theatres

Operating rooms utilise a number of surgical lamps and general lighting fixtures to assist the clinical staff and the surgeon working at the surgical site.

A complex may have two or more totally separate systems and hundreds of different settings.

This is why most operating lighting systems are connected to digital control panels that can adjust their colour temperature (e.g. warm/cold), intensity and focus and in some cases, the RGB colour mix as some procedures need to be done under full green or blue lighting.

The software can then easily store these settings and change between presets so that the entire lighting system can re-arranged with the touch of a button.

Integration of the software with other hospital systems can ‘connect’ the lighting system with safety, backup power and alarm systems, for easier maintenance, logging and reporting.

Entoli Medical is one company that manages to integrate software and hardware to allow full control of video switching, recording, cameras and lighting and is compatible with most suppliers of medical AV. Learn more about how they achieve this by visiting their website.

GPS tracking system for delivery companies

One of the oldest and most prolific examples of an integrated hardware solution is the combination of GPS and traffic monitoring systems that delivery companies use.

These systems utilise data from traffic cameras and position data from GPS systems to predict the best route for delivery drivers. In turn, this helps deliveries stay on schedule.

Automated robots for warehouse management

When you have a warehouse with thousands of items stored in boxes finding the right item can be a tedious task.

This is why the biggest warehousing companies have adopted integrated systems with automated robots that use data from warehousing databases to easily find and retrieve items from anywhere in the warehouse.

This saves a lot of person-hours during the daily movement of inventory in and out of the warehouse.

Food quality control systems for restaurants

Monitoring the income of produce and the storage requirements are vital for the smooth operation of food venues.

This is why restaurants use a system of barcode scanners and thermometers to ensure that every food item is used before its expiration date and that it’s stored properly in conditions that prevent the growth of bacteria.

Food waste is also reduced since the staff is instantly alerted about failures in storage equipment that can cause food items to spoil.

Digital fever scanning and alert system for venues

To limit the spread of highly infectious diseases like Covid-19 venues shouldn’t allow people with high fever to enter closed spaces where a large number of people gather at one time.

One solution is to have someone check the temperature of the entrants with a handheld thermometer. However, this is a slow process that disrupts the business.

A better solution is to install automatic thermal cameras that can read the body temperature of multiple people at the same time and alert venue owners when they detect a person with an abnormally high body temperature.

ITSL Group, a UK AV installation company and system integration already provide such a service. You can learn more about how thermal fever scanning works by visiting their website.

How can hardware integrated systems directly increase profits?

On the whole, when using a companion App or other integrated system, you can directly influence the profit margin of your business, increase customer satisfaction and differentiate your products in the marketplace.

- Increasing the quality of work – by constantly monitoring and controlling the process with the use of a software application your business can fully automate quality control.

- Monitoring for production failures – using a system of connected sensors and gauges you can be alerted of a possible failure in the production line that would slow your output.

- Decreasing the need for manual labour – since your devices can share information between one another and make the necessary adjustments less time is spent on manual calibration

- Eliminating bottlenecks in the production – when you have software that can monitor and analyze data from the entire production line you can quickly spot where bottlenecks are happening and eliminate them.

- Improve inventory control – When your warehouse database is connected to a proper analytics dashboard you can analyze and predict how your inventory is moving and what you need to keep in stock.

- Make complicated hardware setups easier – Sometimes your hardware will need to be adjusted and calibrated differently for every job. With an integrated software solution, you can easily save your settings and reuse them again when needed.

What does a company need to implement a hardware integrated solution?

In the case of a companion App, the electronics need the capability to communicate with outside devices and a protocol or ruleset for communications.

This is usually designed from the outset and Blue Tea can assist with the protocol design for the firmware. For applications to connect industry-standard hardware together most of this could be pre-existing.

The software solution is where most companies will need extra help. Blue Tea can help you with the development of the software that will control and monitor your entire production process from start to finish.

We build bespoke applications for our customers that are specifically tailored to the needs of their business.

Learn more about our services by visiting our page dedicated to hardware integration!